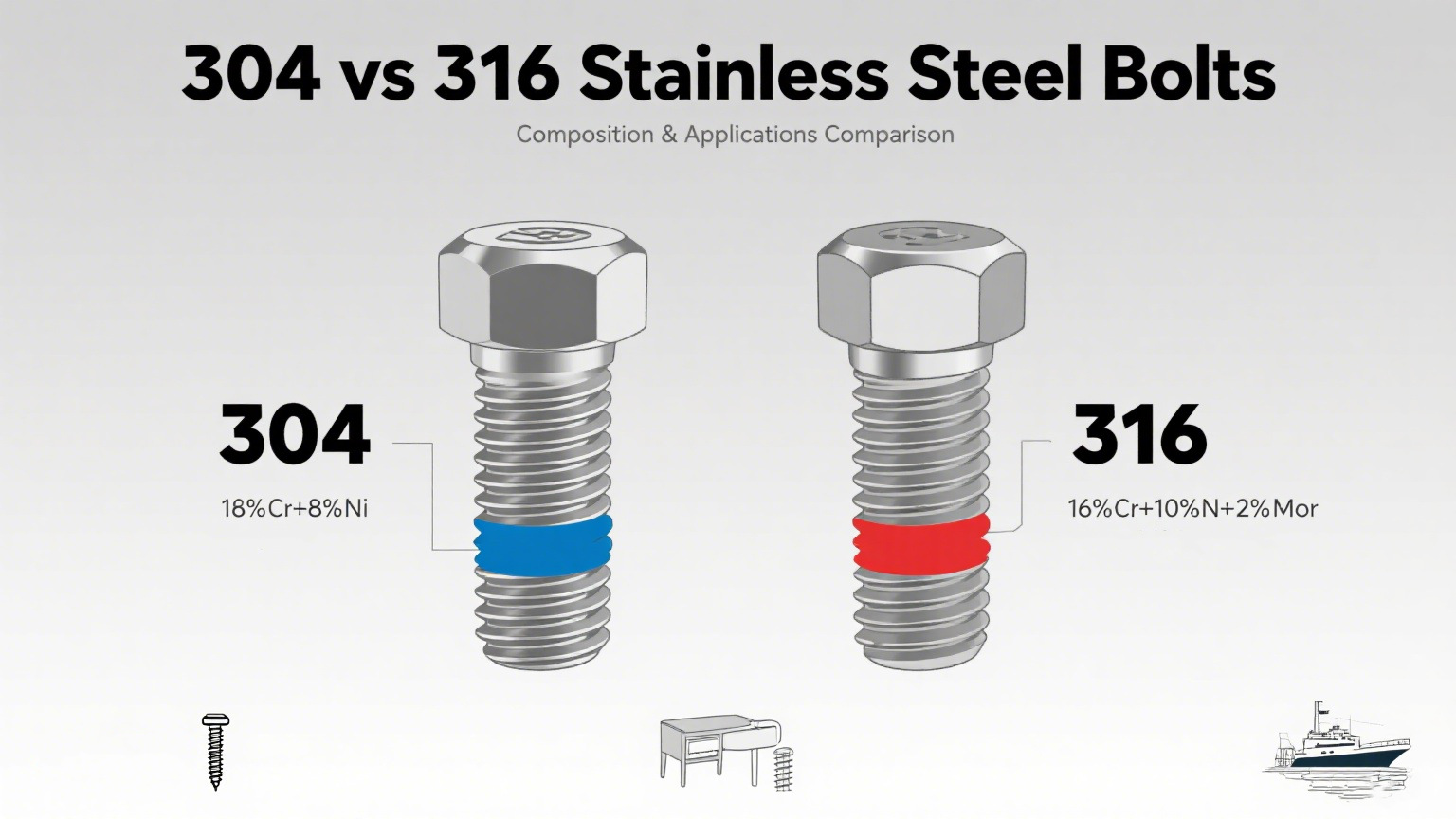

When engineers, builders, or manufacturers choose stainless fasteners, they almost always weigh between 304 stainless and 316 stainless steel bolts. Both are manufactured from premium austenitic stainless steel raw materials that provide great strength, reliability, and good corrosion resistance capabilities. There is a difference in performance as well as cost, so be sure you're picking the right steel bolt for your job!

What Are Stainless Steel Bolts?

Stainless steel bolts are essential fasteners designed to withstand rust, wear, and environmental challenges. Among them, 304 stainless steel bolts and 316 stainless steel hex bolts are the most widely used. The choice between these two depends on whether general durability or superior corrosion resistance is required.

304 Stainless Steel Bolts

304 stainless steel bolts are the most common type of stainless fasteners. They are affordable, easy to source, and highly versatile. With good corrosion resistance, they are used in:

Building construction

Machinery and equipment assembly

Food processing equipment

General outdoor structures

Advantages of 304 Stainless Steel Bolts:

Cost-effective

Widely available

Strong and durable

Limitations:

Not ideal for marine or chemical environments

Less resistant to chlorides compared to 316 stainless

316 Stainless Steel Bolts

Stainless steel 316 is your best bet if you're looking for something more rigorous. The addition of molybdenum makes these bolts resistant to corrosion, and they do particularly well against salt water and nasty chemicals - which is why you'll see them used as standard in:

Marine engineering

Chemical processing

Pharmaceutical manufacturing

Coastal construction

Advantages of 316 Stainless Steel Bolts:

Outstanding durability

Excellent resistance to chlorides and chemicals

Longer service life in harsh environments

Limitations:

Higher cost than 304 stainless

304 vs 316 Stainless Steel Bolts: Performance Comparison

| Property / Feature | 304 Stainless Steel Bolts | 316 Stainless Steel Bolts |

|---|---|---|

| Chemical Composition | Cr 18-20%, Ni 8-10.5% | Cr 16-18%, Ni 10-14%, Mo 2-3% |

| Tensile Strength | ≥ 520 MPa | ≥ 530 MPa |

| Yield Strength | ≥ 210 MPa | ≥ 220 MPa |

| Elongation | ≥ 40% | ≥ 40% |

| Hardness (HB) | ≤ 187 | ≤ 187 |

| Corrosion Resistance | Good, General Environments | Superior, Saltwater & Chemicals |

| Heat Resistance | Up to ~870°C | Up to ~870°C,More Stable |

| Cost | More economical | More economical |

Which Should You Choose?

Choose 304 stainless steel bolts if you need an economical, versatile, and durable option for general applications.

Choose 316 stainless steel hex bolts if your project involves marine environments, exposure to saltwater, or harsh chemicals where superior corrosion resistance is essential.

Final Thoughts

Bolts of 304 stainless steel and 316 stainless steel are strong and solid, but they have their own applications. If you want a cheap alternative, then 304 is definitely for you. However, if the ultimate longevity and superior corrosion resistance are important, 316 stainless steel fasteners are the best choice.

By carefully evaluating your environment and budget, you can confidently select the right stainless fasteners to ensure long-lasting performance.If you have any related product needs, you can contact us, and we will provide you with professional technical guidance and high-quality, cost-effective products.